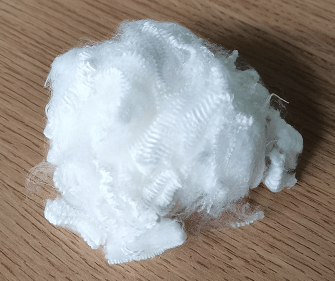

Low Melting Point Fiber : COPET Fiber

Low-melting PET fiber is a special type of sheath-core fiber that's produced by composite spinning general PET and modified low-melting PET.

Anshun low-melting fiber can be melted at a lower temperature(110~180℃) and can be bonded with other fibers at a lower processing temperature than general PET fibers, and the PET fiber, this feature makes it particularly suitable for use in the production of industrial non-woven fabrics, filter materials, shoe materials, and sanitary products.

Our low-melting fiber is a high-performance material that provides enhanced efficiency and quality in production. Its unique characteristics and versatility make it an important component in the manufacturing of a wide range of products.

| Product Category | Melting Points(℃) | Denier(D) | Length(mm) | Characteristics | |

|---|---|---|---|---|---|

| Bi-component Fiber | CO-PET/PET | 110、120 | 2-15 |

51-190 (Customizable) |

N/A |

| 180 | |||||

| Flame-Retardant CO-PET/PET | 120 |

|

|||

| ECO-AN® CO-PET/PET | 120 | Biodegradable Low-Melting PET Fiber | |||

| 180 | |||||

Remark:

|

|||||

| Test Methods | Parameter | Parameter Description | Result | |

|---|---|---|---|---|

|

50% Flame-Retardant Fiber 50% Anshun Flame-Retardant CO-PET/PET |

50% Flame-Retardant Fiber 50% Others Flame-Retardant COPET/PET |

|||

| GB/T 20284 |

LFS |

N/A | Yes | Yes |

| THR600S(MJ) | Total heat release at 600s | 10.670382 | 56.81425 | |

| SMOGRA(m2/s2) | Smoke generation rate index | 1.176446 | 11.043008 | |

| Burning drips and fragments | N/A | No | No | |

| Burning phenomenon | N/A | No droplet, no continuous burning | Burning residue will continue to burn in case of fire | |

| Combustion performance level | Fire-proof level | B1 | B2 | |

| Smoke level | s1 | s3 | ||

| Drip level | d0 | d0 | ||

| Remarks: The burning result will vary according to the flame-retardant fiber ratio and composition of the sample. | ||||

|

Sheath-core Structure |

Description |

|---|---|

|

|

| Product Category | Melting Points(℃) | Denier(D) | Applications | |

|---|---|---|---|---|

| Bi-Component Fiber |

CO-PET/PET Flame-Retardant CO-PET/PET ECO-AN® CO-PET/PET |

120 | 2-6 | Industrial non-woven fabrics, filter materials, shoe materials, sanitary materials. |

| 6-15 | Industrial non-woven fabrics and other applications... | |||

| 180 | 2-6 | Industrial non-woven fabrics, filter materials, automotive materials. | ||

| 6-15 | Industrial non-woven fabrics and other applications... | |||