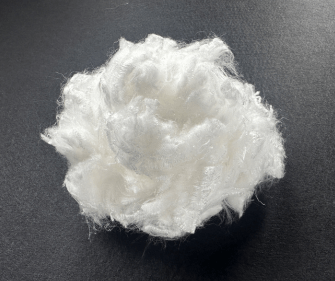

OLIGOTEX® Low Melting Polyeste Staple Fiber :

OLIGOTEX® low-melting-point polyester staple fiber is a functional fiber material with special thermal properties. It is usually made by composite spinning of two or more types of polyesters with different melting points. Its core feature lies in that when the temperature reaches a specific range, the low-melting-point components on the surface or inside of the fiber can melt, thus bonding with other fibers or materials, achieving adhesive-free bonding and forming a stable structure.

(1)Easy heat bonding: This fiber has a relatively low melting point. When heated, it can rapidly melt and bond with other fibers, forming a firm structure.

(2) Safety and environmental protection: The low-melting-point polyester staple fiber has excellent bonding performance. Compared with traditional adhesives, it can achieve bonding without the need for additional chemical adhesives. This not only reduces production costs but also minimizes the potential harm to the environment and human health caused by the residue of chemical substances. At the same time, by controlling the melting point and the physical and chemical properties of the fiber, different degrees of bonding strength and softness can be achieved to meet diverse application requirements.

| Denier(D) | 4-15 |

|---|---|

| Length(mm) | 25-190 |

| Melting Point(℃) | 110/130 |

| Color | White / Black / Dope Dyed |

| phosphorus content(ppm) | ≥3000 |

(1)Industrial non-woven

(2)Building material

(3)Filter material

(4)Shoe material

(5)Automotive interior